The surface of the main parabolic reflector of the radio telescope comprises some 250 panels. These have 1-cm diameter perforations, which prevent the telescope being used at wavelengths below about 2 cm, or a frequency of 15 GHz. In addition, the rms error over the surface is about 2.5 mm, which similarly prevents useful operation above that limit. A programme to replace the surface panels with solid panels with a lower surface error began in 1998. After two years of developing panel-making techniques, production of new panels got under way in 2000.

The new antenna surface panels are being built onto the old backing frames removed from the telescope, with extra ribs to provide greater rigidity. The mean surface tolerance of the individual panels beign produced is currently averaging 125 microns, which is well within specification. The panel production rate is currently at six panels every ten days, and this will improve in the future.

Steps in the production process are illustrated below.

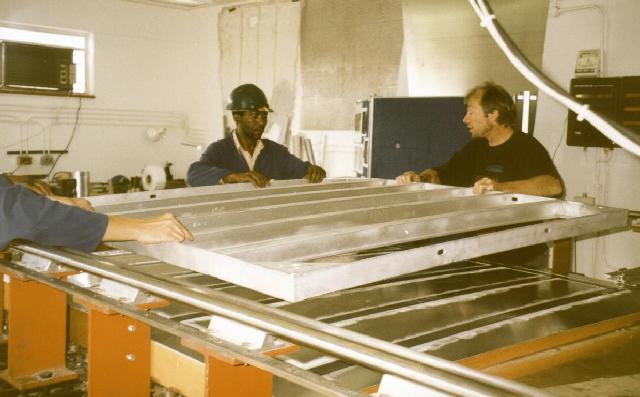

The picture below shows the frame with the new ribs welded in, supported by Bruce Cross and Jacques Grobler.

The frame is lowered onto the resined panel by Jacques Grobler, Simon Morake, Amos Kekae and Bruce Cross.

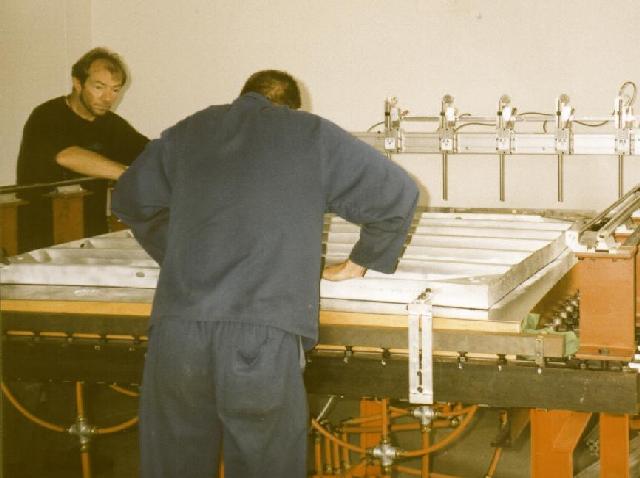

The frame is pushed down onto the resin by Bruce Cross and Jacques Grobler.

The resin takes about eight hours to set. The edges of the panel are then trimmed and the panel is screwed onto holes predrilled in the frame. The completed panel is shown below supported by Bruce Cross. The surface shape of the panel is then measured with electronic probes on a square grid at intervals of 10 cm. The accuracy of the height measurement at each point is about 15 microns.

Before installation, batches of panels are spray painted matte white in a spraying shed. Two panels are seen hanging in the shed before painting.

Here Jacques Grobler, Simon Morake and Amos Kekae manouever the panel into position.

The final panel of the first batch of five is secured by Jacques Grobler as Simon Morake assists next to the forklift.